Every customer and every project is different and the solution is always individual. Together we realize mechanical engineering project or the production of your parts within the framework of contract manufacturing. A small excerpt from our customer list and a few selected projects should give you an insight into our work.

- Lenser Präzisionstechnik GmbH & Co. KG

- Maschinenbau Silberhorn GmbH

- EPUCRET Mineralgusstechnik GmbH & Co. KG

- Hilgert Maschinen AG

- Siemens AG

- PCK Raffinerie GmbH

- Siemens Gusstechnik GmbH

- Parker Hannifin GmbH

- Finze & Wagner EMSR Ingenieurges. mbH

- DEMMELER Maschinenbau GmbH & Co. KG

- BIMATEC SORALUCE Zerspanungstechnologie GmbH

- and soon you!

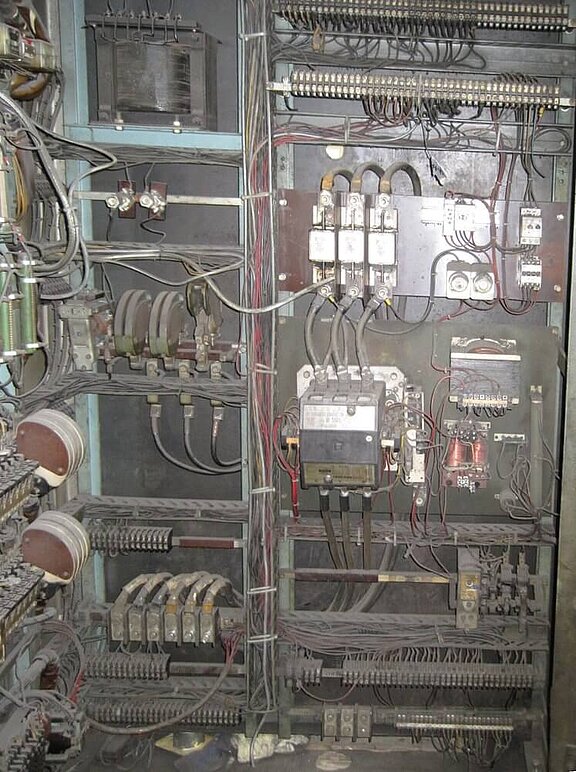

A complete general retrofit has been performed on the machine with the following work performed (extract):

- Full colouring

- All drives redesigned

- All ball screws at axes replaced

- Conventional control replaced by a CNC control

- All electrical equipment incl. cables replaced

- All guide tracks overhauled and surveyed

- Machine bench, crossbeams, crossbeam support and spindle gear box scraped

- Guide tracks on machine bed and both stands scraped

- Drive systems overhauled and/or rebuilt with respect to interpolation

- capability of the main axes X, Y and Z

- All gearboxes removed at the feed axes and replaced by servo motors with planetary gears

- Central drive of crossbeam on gantry drive rebuilt

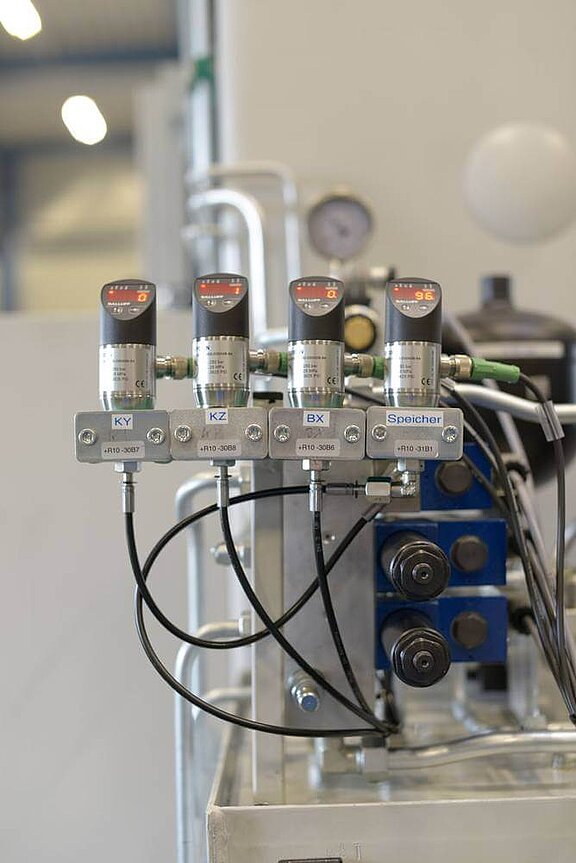

- Bench hydrostatic system replaced by a completely new system

- Clamping system of bench drive worm overhauled to realise bench interpolation

- Cooling system with oil-water heat exchanger installed for cooling of bench drive lubricating oil

- Existing DC main engine replaced by water-cooled AC asynchronous motor

- Cooling system with oil-water heat exchanger installed for cooling of main spindle drive lubricating oil

- CNC-controlled temperature compensation of spindle gear box linear expansion in different operating states

- Complete geometric adjustment of machine according to measurement report

- Determination of linear measuring system measurement errors with laser interferometer, compensation by means of CNC control

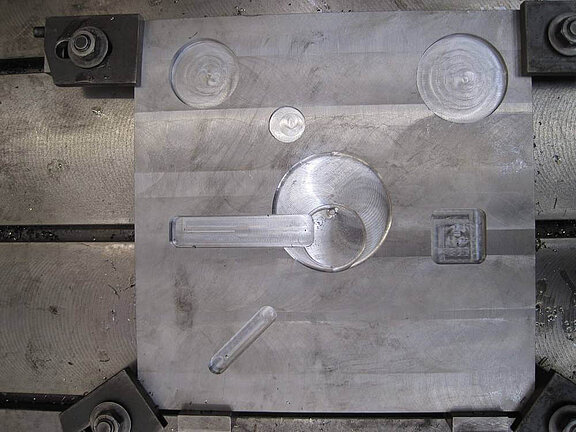

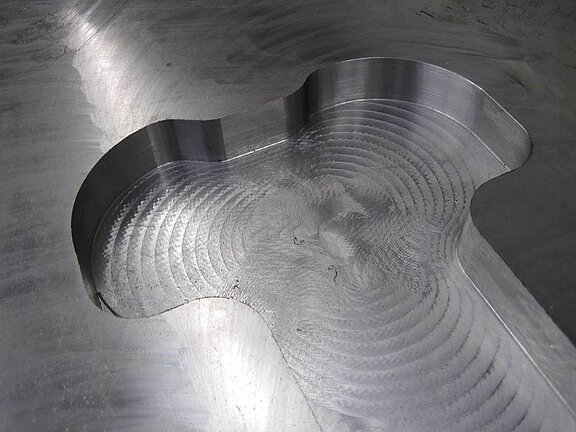

Mechanics:

- New custom colour

- Redesign and new production of axle drives with Wittenstein alpha planetary gears and Siemens 1FK7 servomotors, as well as redesign and assembly of new ball screws

- Reworking of all sliding guides and application of all supports

- Geometric adjustment

- New guideway tops

- Complete replacement of milling spindle drive, speed gearbox and milling spindle bearing

- Completely new hydraulic system adapted to the new axle drives

- Cleaning and inspection of all lubrication systems, installation of new lube pumps

- Installation of optical length measuring devices for the x, y, w axles

- Installation of a rev transmitter for the z axle

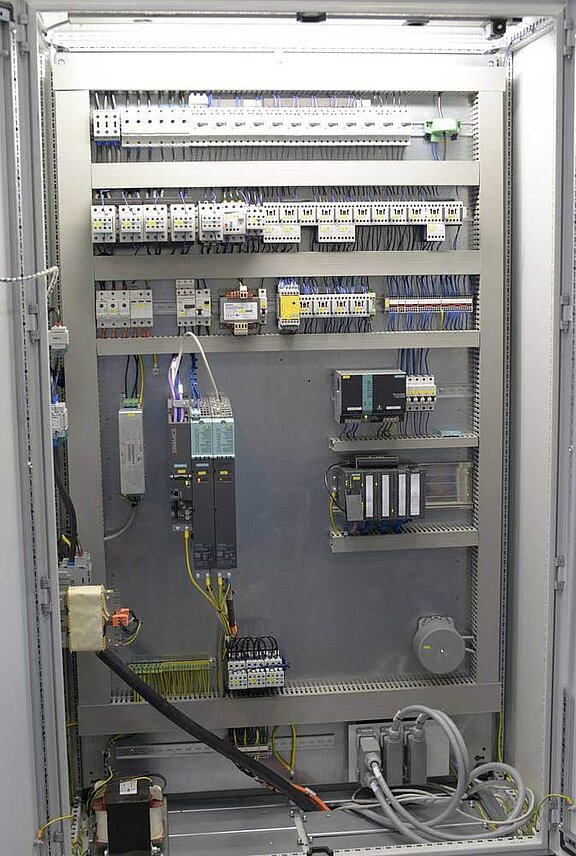

Electrics:

- Redesign and programming of a new, customised machine control system; Siemens S7-300 controller, Siemens Sinamics S120 drive control system

- Heidenhain ND780, HMI Siemens KTP600 position indicator

- Creation of circuit diagrams

- Manufacture of new control cabinet with air conditioner

- Replacement of nearly all machine wiring, sensors and actuators

What we did:

- Acquisition of the machine on behalf of the customer.

- Transport to our facility.

- Replacement of guideway coverings.

- Reworking of the hydraulic system.

- Reworking of all lubrication systems.

- Transport to the customer and subsequent re-installation.

- Geometric adjustment according to manufacturer's specifications.

- Redesign of the entire electric equipment, incl. creation of circuit diagrams.

- New control concept based on Heidenhain TNC124 + Siemens S7 PLC, incl. software development + parametrisation.

- Rewiring of the entire machine.

- Installation of new optical length measurement systems. Installation of an angle measuring device in the middle of the table to indicate the table's angle of rotation.

- Configuration of new direct drive motors and drive control systems.

- Manufacture of the new control cabinet and operator control module.

- Startup and handover of the machine to the customer

What we did:

- Redesign of the entire electric equipment, incl. creation of circuit diagrams.

- New control concept based on Siemens PLC control system 840Dpl, incl. NC software

- and parametrisation.

- Configuration of new direct drive motors and drive control systems.

- Manufacture of the new control cabinet and operator control module.

- Startup and handover of the machine to the customer

Job Order Production of Control Cabinet

Complete installation of control cabinets according to customer specifications. The required material can by supplied by the customer or purchased by us.

Sedin 1525 Vertical Turning and Boring Mill

Redesign of the entire electric equipment, incl. creation of circuit diagrams.

Startup and handover of the machine to the customer